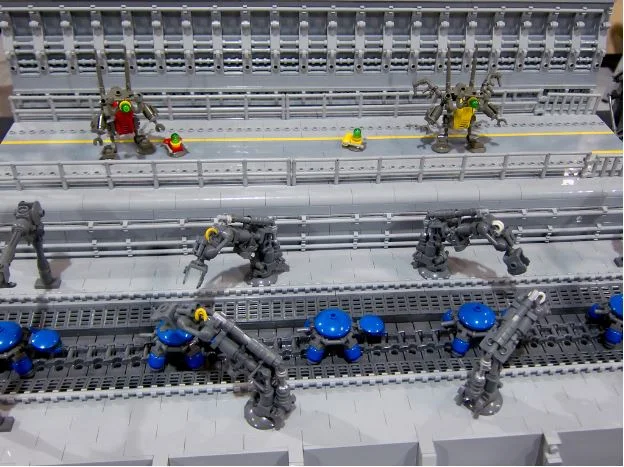

Credit: Paul Albertella

This year, the American manufacturing industry has made a big resurgence. Over 800,000 new jobs were created since the 2010 recession. It’s an excellent time to be a factory owner, and manufacturing firms should be taking advantage.

One of the most important parts of production is ensuring a consistent level of high quality in your goods. In other words, you should make sure that every single product on your production line comes out perfect. Here are some of the measures you can take to improve your processes and provide the greatest products.

Use Top-Notch Equipment

Sometimes improving your machinery can change your products for the better. Many companies offer custom-built manufacturing equipment for whatever you’re building. If you’re making children’s toys, getting state-of-the-art plastic molding equipment might help. If you’re manufacturing books and stationery, maybe you need an innovative cutting machine.

You can also find equipment which helps to ensure quality is up to standards. For instance, moisture gauges can help prevent products from getting ruined by moisture. It’s particularly useful for plants manufacturing goods such as tobacco and food products. But preventing moisture can help all kinds of manufacturers and also save your building from depreciating. Or if you're looking to make custom-made wooden furniture, you´re going to want to purchase the best table saw on the market.

It can also help to equip employees with the right equipment. Giving your supervisors tablets might help out. There are many apps created for business productivity and even some specifically for manufacturing. They can help your team ensure peak performance across the production line.

Test Products

Checking the quality of your products before sending them out to your clients is crucial. One poor product can harm your reputation a great deal. A batch of products with malfunctions will be even worse.

Make sure you have employees to ensure the quality of finished products. It might even help to take a product off the production line to ensure that quality is on point thus far. Identifying problems in advance can help prevent you ending up with a bad batch.

Improve Factory Efficiency

Improving the efficiency of your factory will have a significant impact on product quality. You can make every process of your business run smoother and ensure everything is up to par.

Making use of technology can often help you improve the efficiency of your firm. For instance, you can find software to help you keep track of client orders. By determining how many products you need to supply, you can ensure you have the time and resources needed to fulfill the demand.

Improving time-efficiency will also help a great deal. Make sure your workers are not bogged down by any distractions in the workplace. Keep your workers up-to-date on any changes in the process to ensure nothing slows down.

Develop And Train Your Workforce

Your workforce is your key ingredient for successful production. You need to have motivated employees who know how to do their jobs right to ensure products come out right.

From the hiring process, you should hire people who are right for the job. Every member of your production line needs to be alert and watch out for any potential malfunctions. Do what you can to keep your employees stimulated and reward them well.

Training is also essential in manufacturing. You need to make sure every worker knows how to operate their part of the production line. When new equipment comes in, make sure you know how to train employees to use it. It can help ensure that nothing goes wrong and products come out perfect.